- Higher output alternators require more effort to spin than a lower amperage alternator when the alternator is under a load. This additional effort places more strain on the alternator drive belt.

- If for any reason the alternator pulley is not aligned perfectly with the other pulleys on the engine, the alternator drive belt will slip. A straight edge can be used on the face of the pulleys to verify the belt is aligned properly.

- V belt applications should have no more than 3/8 inch belt deflection after the alternator has been installed. Serpentine belt applications should use a belt length that places the spring belt tensioner in the CENTER of it's travel. If the spring tensioner is too far outside of it's operating range in EITHER direction, the belt will slip.

- Vehicles with poor belt "wrap" (see photo) will be more prone to belt slip than vehicles that have better belt "wrap" around the alternator pulley. If necessary, fabricate brackets to mount an additional free spinning idler pulley to ride on the back of belt and "force" the belt to "wrap" around the alternator pulley further.

- Lower amperage alternators will not slip the belt as badly as a higher amperage unit, and can utilize a larger diameter alternator pulley than the same unit in a amperage configuration. Larger pulleys grip better, but will not charge at idle on some higher amperage alternators.

- 170 amp S series and 250 amp Elite series units are the best choice for high RPM racing applications.

- Single V belt and 4 rib serpentine belts will start to slip at about 150 amps worth of load. For minimal belt slip, 240 – 370 amp alternators should not be driven by anything narrower than a 6 rib serpentine or dual-V belt drive setup.

- Calculate pulley ratio by dividing the diameter of your crankshaft pulley by the diameter of the alternator pulley. For example, a 6 inch crank pulley with a 2 inch alternator pulley will yield a 3:1 pulley ratio. (6 divided by 2 = 3) This means that the alternator will be spinning 3 times the engine RPM- i.e. the alternator will be spinning 18,000 RPM at 6,000 RPM engine speed. G series alternators are rated to 18,000 RPM, while S and Elite series alternators are rated to 20,000 RPM.

- It is ABSOLUTELY IMPERITIVE that a properly sized positive AND ground cable be run directly from the alternator to the terminals of the battery.

- Improperly crimped, or oversized ring terminals on your charge and ground cables can easily damage the alternator or cause a fire. The size of the hole in the ring terminals you use MUST fit the diameter of the stud or bolt that they go on PERFECTLY. If the hole in the cable end is oversized, the high resistance connection will burn off amperage in the form of heat, and in some cases can melt off the stud.

Frequently Asked Questions

Q: Will the installation of a higher amperage alternator damage my vehicle or my battery(s) ? A: No. As long as the battery(s) are in good condition, and the correctly sized alternator charge and ground cables are installed properly, nothing will be adversely effected on the vehicle

Q: My vehicle's alternator is computer controlled. Will a higher output alternator work properly in my application? A: Yes. As long as the alternator is installed properly. (some PCM controlled vehicles require specific cable routing, instructions are provided) A MechMan high output alternator will still work fine and provide more amperage than the OEM alternator.

Q: If I install a higher output alternator, will my charging voltage be higher than stock? A: That depends, depending on the part number, most MechMan alternators are designed to operate at the OEM voltage. This is done intentionally, so that the vehicle is not harmed by higher than stock charging voltage. A higher AMPERAGE alternator will keep the voltage in the vehicle closer to OEM voltage when drawing more current from the battery. If higher than OEM charging voltage is required, contact a sales rep about custom ordering your alternator with adjustable voltage.

Q: Will a higher amperage alternator draw more horsepower from the engine or reduce my fuel economy? A: That depends, the more amperage the alternator makes, the more horsepower is required to turn it. All alternators are regulated, so unless there is a heavy electrical load against the alternator, a higher amperage alternator will not provide any more drag against the engine than an OEM alternator.

Q: Can a 2 pin GM regulator be used in External Regulator applications?

A: NO. The GM 2 pin is ECU controlled and differs highly from a "terminal block" or Mopar/Dodge style regulator. If you are needing external regulation, please call or email to discuss and/or setup.

Q: Can you spin an alternator BACKWARDS?

A: Short answer is YES. Long answer is NO. The alternator will charge spinning backwards but the efficiency drops nearly 40% due to the internal fan not being changed. Special rotors/fans are used in these applications to restore the efficiency, cooling and durability.

Q: My battery is COMPLETELY dead or near dead/nothing happens when I turn the key. Will my alternator recharge it?

A: Yes and no. Yes it will charge the battery but this should be avoided at all costs. Alternators are made to sustain the charge of the battery and cannot recharge a dead or very low battery. The alternator has one job but it’s too much of work and recharging a very low battery or dead battery is just too much for an alternator to take and will shorten its life.

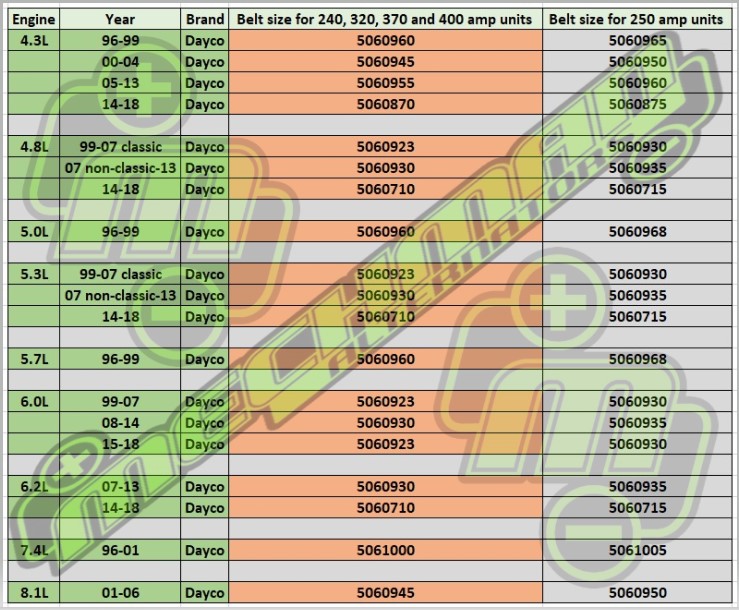

*** POPULAR GM TRUCK /// SUV BELT PART NUMBER APPLICATIONS ***